Air Quality & Corrosion: The Hidden Cost in Pulp and Paper Mills

Airborne contaminants pose significant challenges in pulp and paper mills, leading to corrosion and damage to critical equipment. Corrosive gases, byproducts of essential mill processes, can cause expensive downtime and equipment failures if not properly managed.

Sources of Corrosive Gases in Pulp and Paper Mills

Pulp and paper mills utilize chemical-intensive processes to break down raw materials, bleach pulp, and produce finished products. These processes release harmful gases, including:

- Hydrogen Sulfide (H₂S): Emitted during the Kraft pulping process, where wood chips are cooked in a mixture of sodium hydroxide and sodium sulfide.

- Sulfur Dioxide (SO₂) and Other Sulfur Compounds: Produced during combustion in recovery boilers and lime kilns, and also found in emissions from sulfite pulping.

- Chlorine and Chlorine Dioxide (Cl₂, ClO₂): Utilized in bleaching processes to whiten pulp, creating highly corrosive environments.

- Nitrogen Oxides (NOₓ) and Other Acidic Gases: Resulting from combustion processes in boilers and kilns.

The Hidden Cost of Corrosion in Pulp and Paper Mills

These gases attack metal surfaces and electronic components, leading to corrosion and system failures. Control rooms, electrical cabinets, and sensitive automation systems are particularly vulnerable, necessitating costly repairs and replacements. Unexpected downtime due to equipment failure can halt production, leading to significant financial losses. In severe cases, corrosion-related failures can compromise safety and compliance with industry regulations.

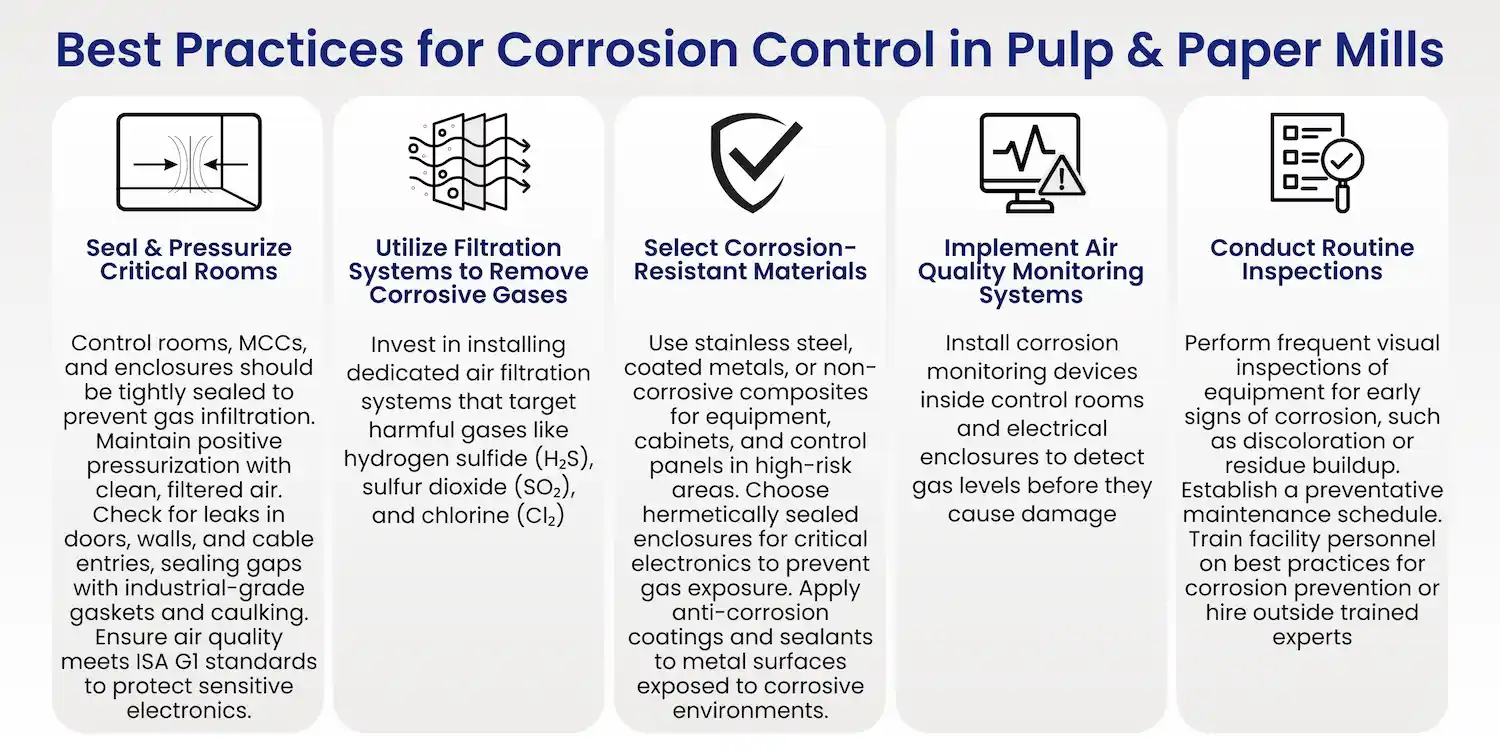

Strategies to Mitigate Corrosion Risk

To minimize corrosion-related damage and downtime, pulp and paper mills should implement the following best practices:

Seal and Pressurize Critical Rooms:

- Ensure control rooms, motor control centers (MCCs), and electrical enclosures are tightly sealed to prevent gas infiltration.

- Maintain positive pressurization by introducing clean, filtered air to push out contaminants.

- Monitor for air leaks in doors, walls, and cable entry points, sealing any gaps with industrial-grade gaskets and caulking.

- Ensure rooms meet ISA G1 air quality standards to protect sensitive electronics.

Utilize Filtration Systems to Remove Corrosive Gases:

- Invest in dedicated air filtration systems that target harmful gases like hydrogen sulfide (H₂S), sulfur dioxide (SO₂), and chlorine (Cl₂).

Implement Air Quality Monitoring Systems:

- Install corrosion monitoring devices inside control rooms and electrical enclosures to detect gas levels before they cause damage.

Select Corrosion-Resistant Materials:

- Use stainless steel, coated metals, or non-corrosive composites for equipment, cabinets, and control panels in high-risk areas.

- Choose hermetically sealed enclosures for critical electronics to prevent gas exposure.

- Apply anti-corrosion coatings and sealants to metal surfaces exposed to corrosive environments.

Conduct Routine Inspections:

- Perform frequent visual inspections of equipment for early signs of corrosion, such as discoloration or residue buildup.

- Establish a preventative maintenance schedule for inspecting and replacing filtration systems.

Train Facility Personnel on Best Practices for Corrosion Prevention:

- Educate staff on identifying early signs of corrosion and proper maintenance procedures.

- Consider hiring external experts for inspection.

PureAir’s Comprehensive Solution

To fully protect control rooms and sensitive equipment in pulp and paper mills, PureAir offers:

Field Service

- Provides expert assessment, installations, and maintenance to control rooms or other site locations to keep air quality at ISA G1 standards.

Equipment

- Industrial Vertical Bed System (IVBS): A high-capacity vertical airflow system specifically designed for industrial environments like pulp and paper mills. This deep bed system eliminates air bypass, ensuring continuous, high-efficiency removal of over 99% of corrosive gases. With an airflow range of 300–5,600 CFM, IVBS provides the high contaminant removal capacity needed to protect critical equipment from corrosive damage.

- Packaged Filter Unit (PFU) A self-contained air purification system available in horizontal and vertical configurations. Engineered for continuous high-efficiency filtration, it manages airflows from 500–3,000 CFM to maintain clean air in sensitive spaces. PFUs remove harmful gases that can corrode electronics, preventing hardware failures, data loss, and costly downtime.

Adsorbent Media

- PP Blend is a specialized media made specifically to target and remove the harmful and odorous gases commonly found in pulp and paper mills

Monitoring Tools

- Environment Corrosivity Monitor (ECMv2): Detects real-time corrosion rates inside enclosures to facilitate easy tracking of air quality in critical environments.

- LIFEGARD™ Media Bed Monitor: Provides real-time data on the life of adsorbent media, alerting when it is time for a media changeout before the media is spent and corrosive breakthrough occurs.

Protect Your Mill’s Future

Poor air quality is more than a nuisance in pulp and paper mills — it’s a direct threat to your equipment, your uptime, and your profitability. The presence of corrosive gases like hydrogen sulfide, sulfur dioxide, and chlorine compounds can silently degrade vital systems, leading to unplanned downtime, costly repairs, and even safety hazards.

With decades of experience and proven solutions tailored specifically for industrial environments, PureAir helps facilities take proactive control of their air quality. From advanced filtration equipment like the IVBS and PFU to powerful monitoring tools like the ECMv2 and LIFEGARD™, PureAir delivers a full-service approach to protect your most valuable assets.

Don’t wait for corrosion to cause a shutdown — contact PureAir today to connect with an expert to build a customized corrosion control plan for your mill.